Design & Develop

- R&D tailored solutions to meet diverse customer needs.

- Support new ideas, efficiency improvements, and trends in the market.

- Comprehensive production process

- Accelerated prototyping in a limited of time.

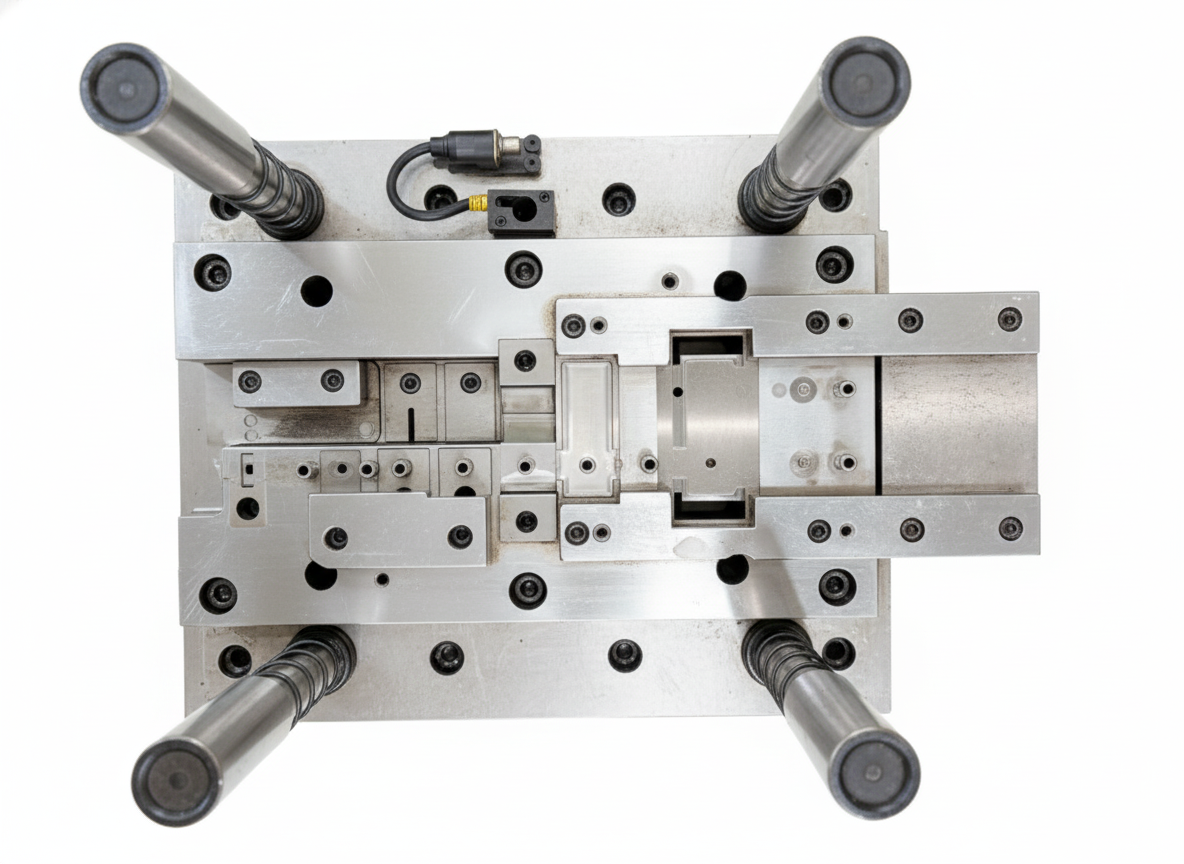

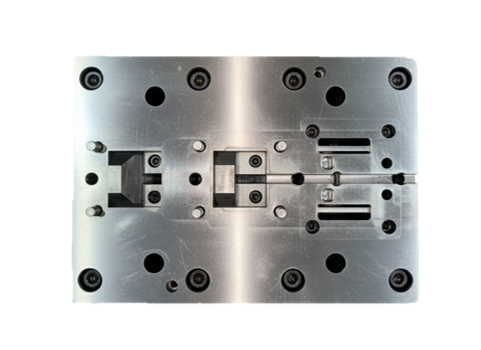

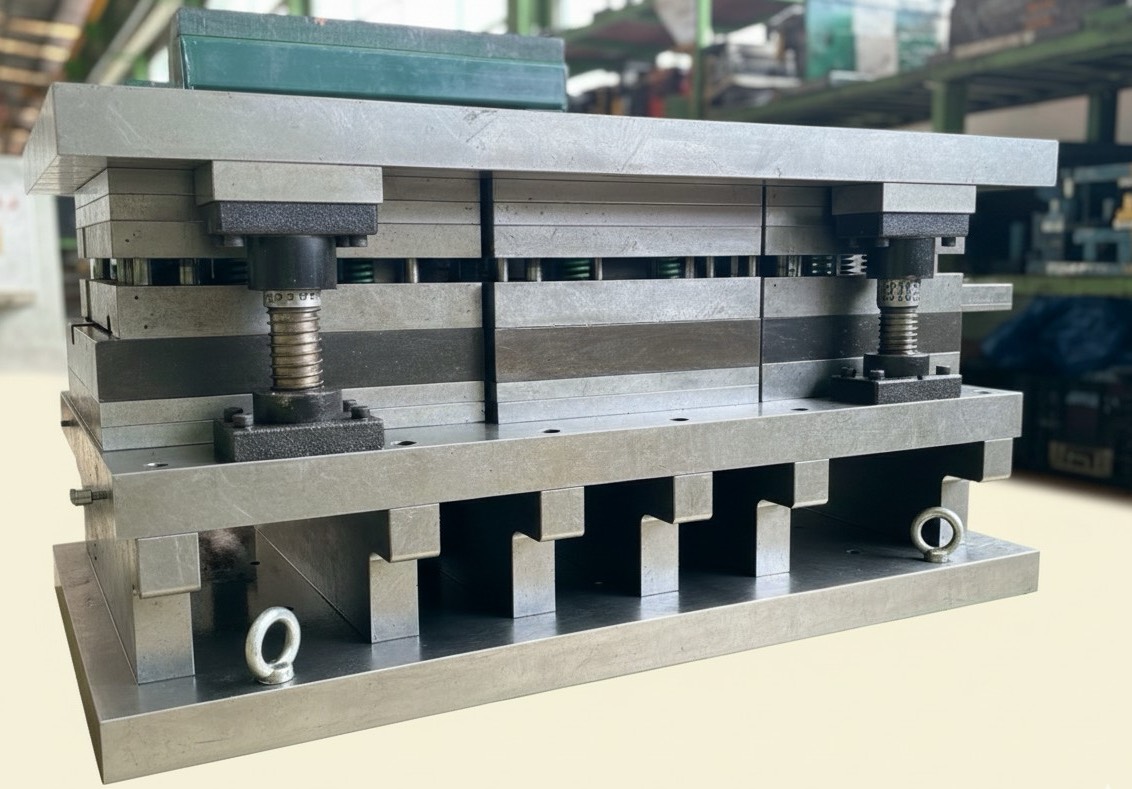

Custom die design based on your drawings or samples

Stamping Die

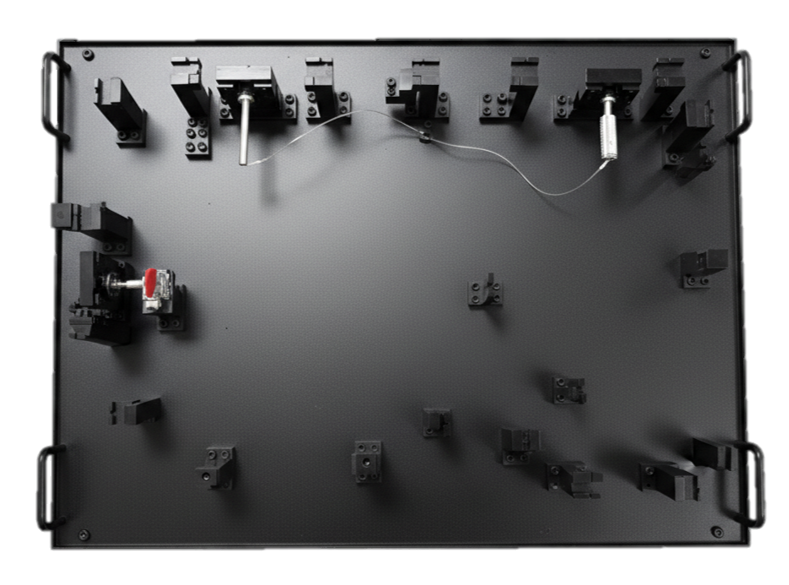

Jig & Fixture

Lead time within 4 weeks (Urgent case : available on demand)

** Quality with 1st trial > 90% **

Customized Tooling Service :

- Tooling designed to match your exact production and punching needs

- High-quality materials and optimized stamping process for the best results

- Developed according to your standard tooling structure for smooth operation

Key Strengths of Our Die Tooling :

- Exceptional durability

For Automotive parts: up to 10 million shots

For Electronic components: up to 100 million shots

- Complete in-house tooling service

- Ultra-high precision

- Low maintenance

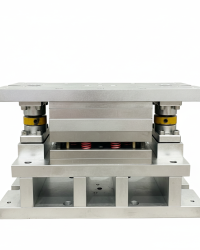

MACHINING CENTER

Machine capability

- High Resolution: Works with micron-level precision.

- High Precision: Accurate positioning for consistent results.

- Complex Workpieces: Supports multi-axis operations, ideal for 3D parts.

- Limitations: Size constraints, specific tools required for hard materials.

- Strong Base Support: Reduces vibration, ensures stable continuous operation.

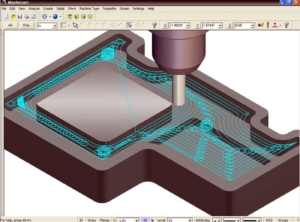

PROGRAM

DESIGN PROGRAM

CAD : Precise and efficient design creation with easy edits and fewer errors.

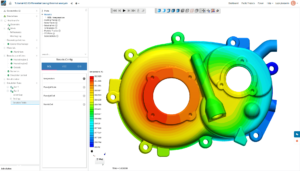

ANALYZE

CAE : Simulates real-world performance to optimize designs and reduce prototyping costs.

SIMULATION

CAM : Automates machining for faster, more accurate, and consistent production.

Quality Control

INSPECTION

3D scan & CMM

- 3D Scan : Reverse engineering Captures precise geometry of objects using lasers or structured light, creating detailed 3D models for reverse engineering and quality control.

- CMM: Measures dimensions of parts with high accuracy using a probe, ideal for precision inspection and quality assurance.

Layout machine

- Measures and marks key reference points on workpieces

- Used for centering, drilling, cutting, or welding alignment

- Enhances accuracy before actual machining or assembly

- Ideal for high-precision tasks like mold making and large metal structures

- Supports both 2D and 3D measurements depending on the model