" Everyday we are improving our efficiency by developing standardized and repeatable process and sharing best practices, Our commitment to consistant manufacturing procedures."

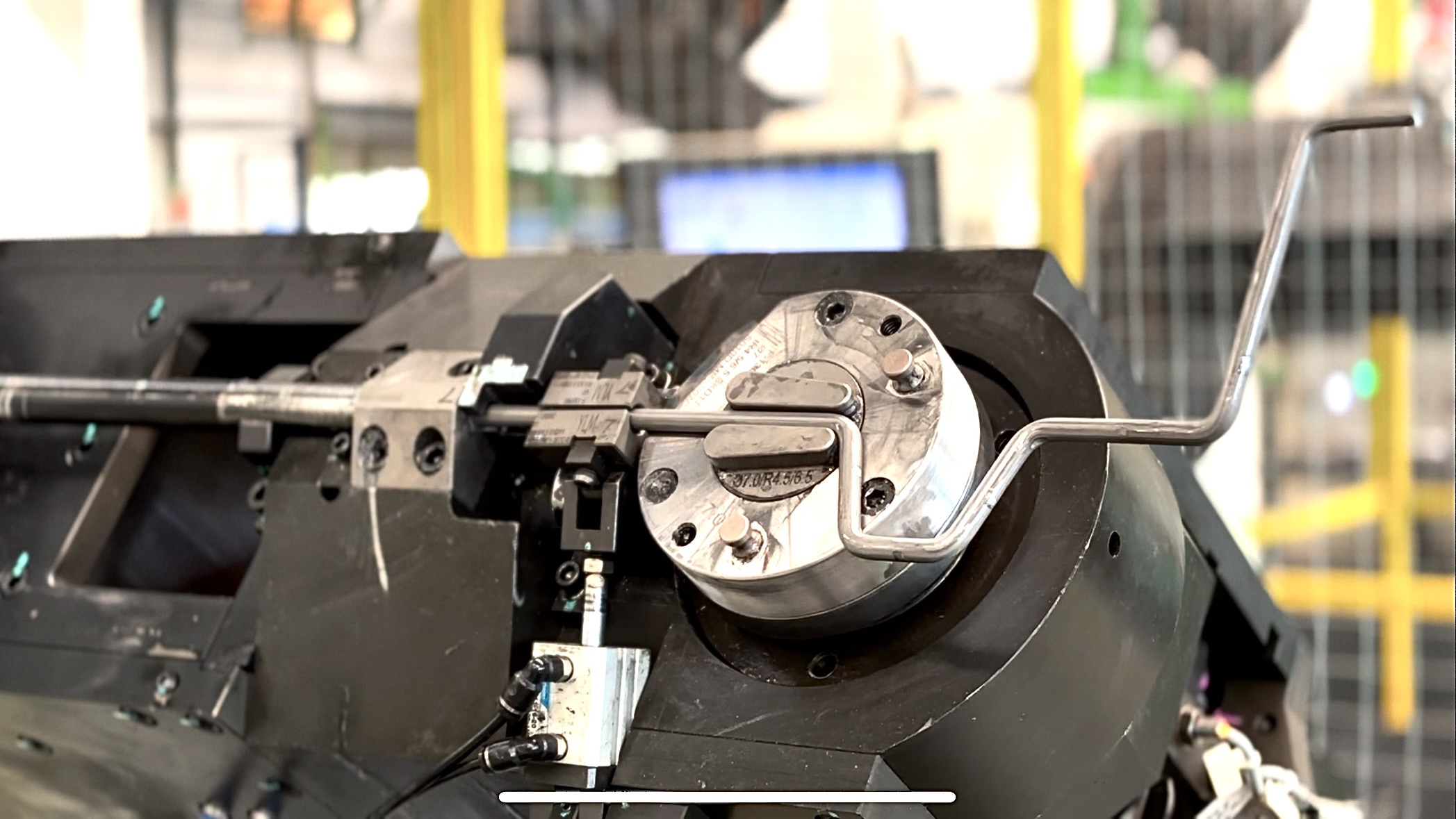

WIRE FORMING

SPT has an established reputation for precision wire forming, capable of producing intricate wire components in various dimensions. Our advanced manufacturing capabilities, encompassing both CNC and manual processes, allow us to tailor our solutions to meet the unique specifications of our customers. As the automotive seating industry undergoes significant transformations, SPT remains committed to developing innovative manufacturing techniques to drive cost efficiency and enhance product quality.

MACHINE CAPABILITIES

The CNC machine is capable of machining with a maximum diameter of 16.0 mm.

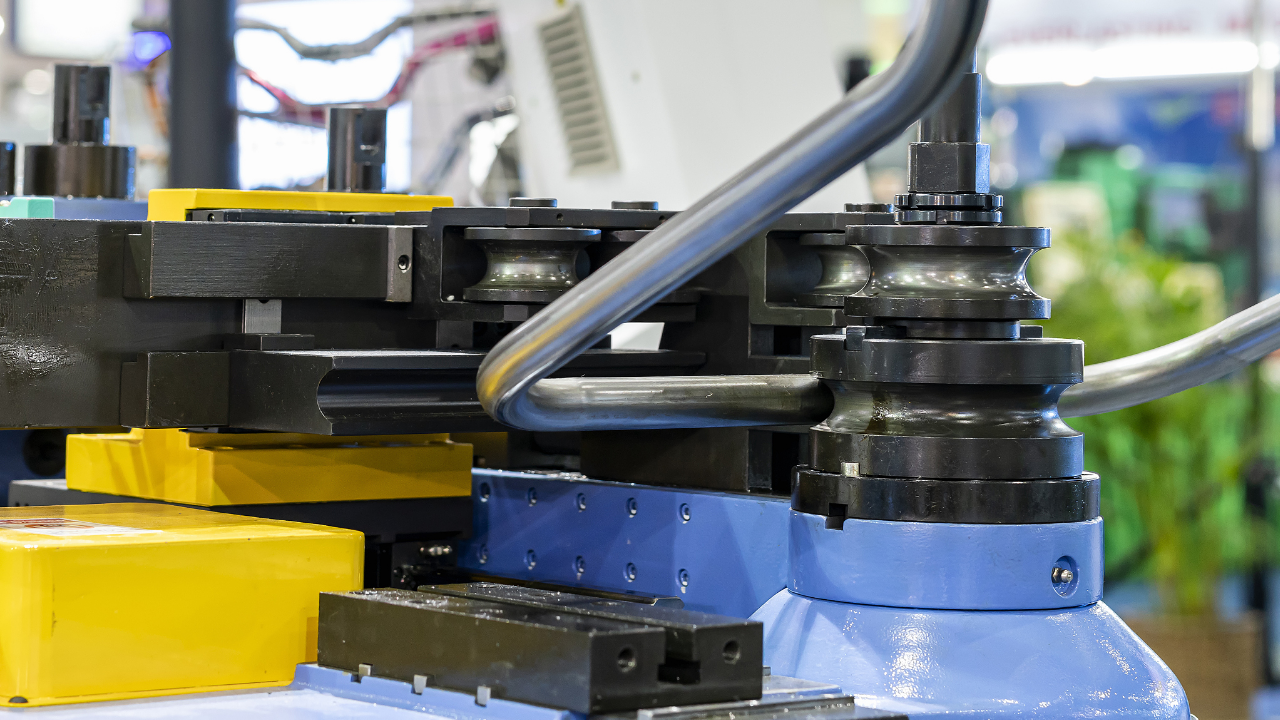

PIPE FORMING

We offer flexible pipe forming solutions, utilizing both CNC pipe bending and press forming techniques to meet the specific requirements of each project.

FORMING PROCESS

- Bending

- Swagging

- Emboss

- Notching

MACHINE CAPABILITIES

Capable of forming with a maximum diameter of 30 mm.

STAMPING

We offers comprehensive stamping services, capable of producing brackets of various sizes and complexities. We utilize a fleet of presses ranging from 35 to 260 tons to process a wide array of materials, from standard low-carbon steel to high-tensile steel. Our in-house die-making capabilities enable us to deliver customized solutions efficiently.

MACHINE CAPABILITIES

- Machine Size: Ranges from 35 to 260 tons

- Stamping Types: Supports both Single and Progressive stamping processesFeed Length: Up to XXX mmMax Workpiece Size: Capable of pressing workpieces with a maximum width of XXX mm and size up to XXX mm

ASSEMBLY

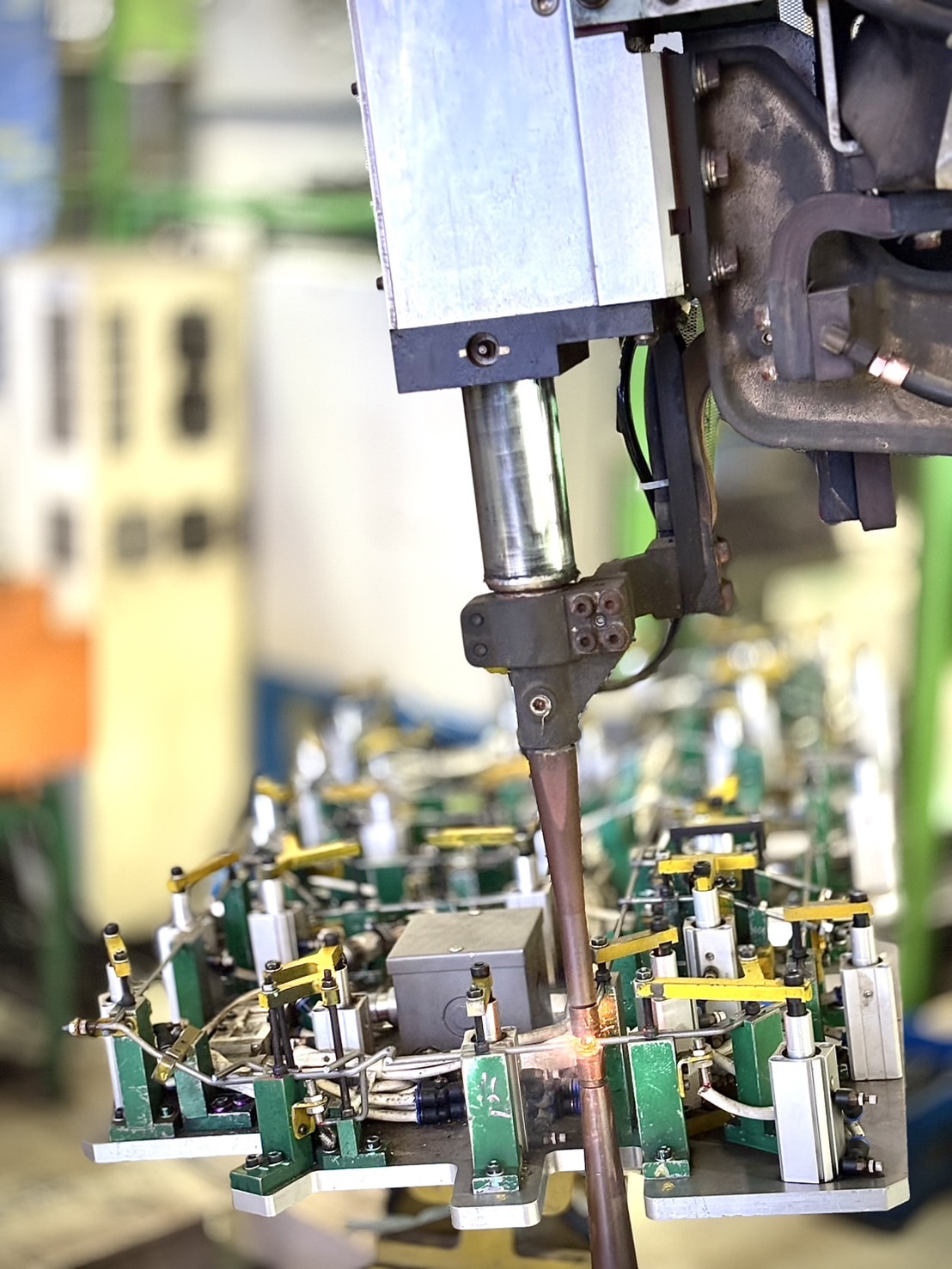

SPOT WELDING

Fast and precise metal joining without the need for filler materials. Ideal for automotive, electronics, and manufacturing thin components with high speed and efficiency.

MACHINE

ROBOT SPOT WELDING

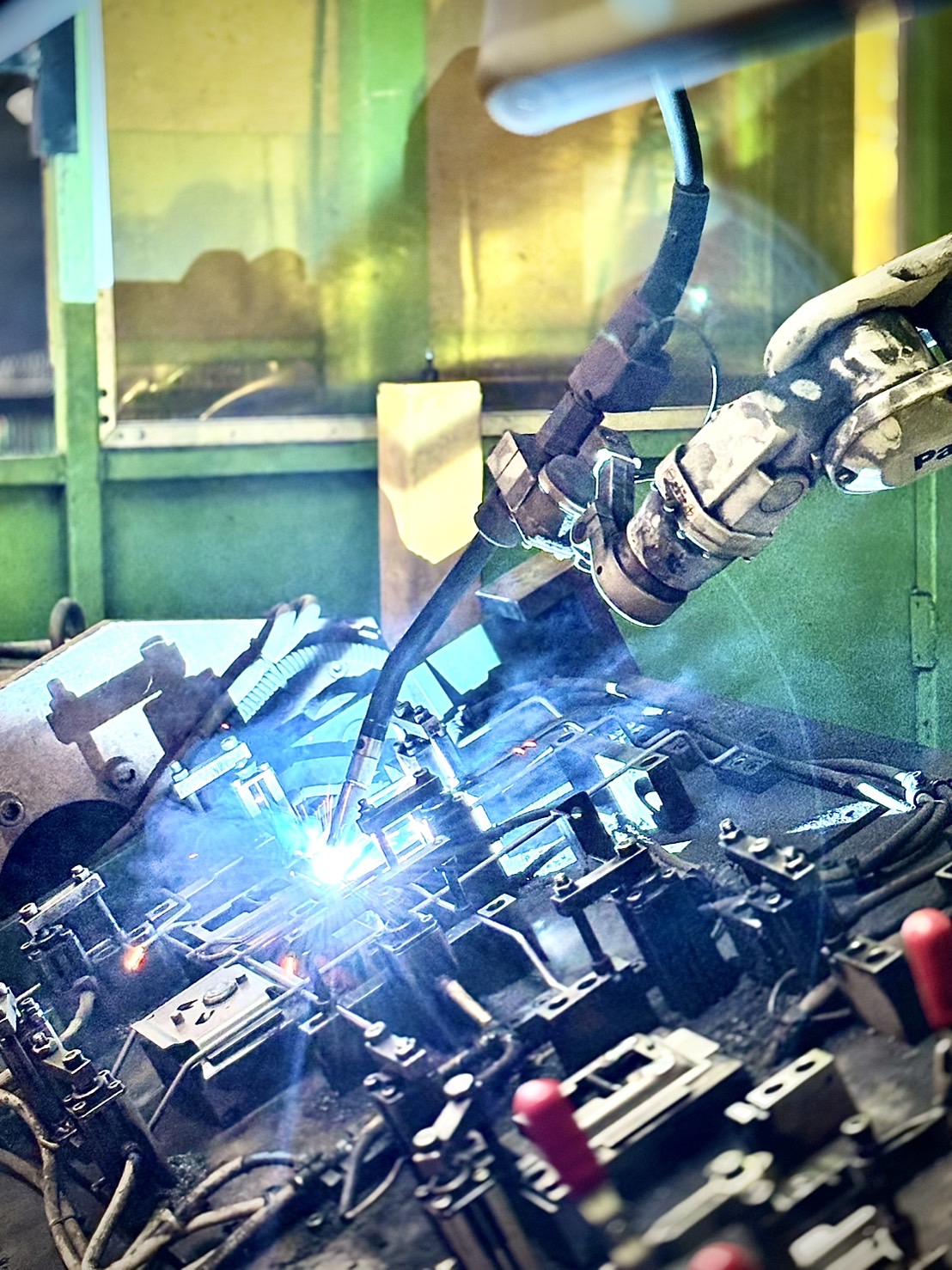

ARC WELDING

Strong and durable metal joining suitable for various materials like steel, stainless steel, and aluminum. Perfect for welding heavy structures and thick materials, delivering stable and robust results.

MACHINE

ROBOT ARC WELDING

PLASTIC INJECTION

Our company provides comprehensive Plastic Injection services, utilizing advanced injection machines to ensure precision and consistency in production. From simple plastic components to overmolded products with enhanced durability, flexibility, and grip, we deliver high-quality solutions tailored to your needs.

MACHINE CAPABILITIES

- Machine Clamp Force: Maximum at 210 tonsMax Workpiece Size: Capable of pressing workpieces with a maximum width of XXX mm and size up to XXX mmStroke :

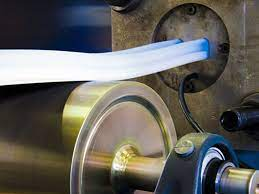

EXTRUSION MACHINE

Our company utilizes extrusion machines to produce continuous profiles of plastic and other materials. This process enables the efficient manufacturing of high-quality components with consistent dimensions and excellent structural integrity.

We are capable of extruding plastic in a wide variety of shapes, ensuring standard-compliant quality that meets each customer’s specific requirements.

MACHINE CAPABILITIES

Supports various materials, including:

- Plastics

- Composite materials